Production Planning

Plan production runs, generate bills of materials, and know your total COGS before you start cooking.

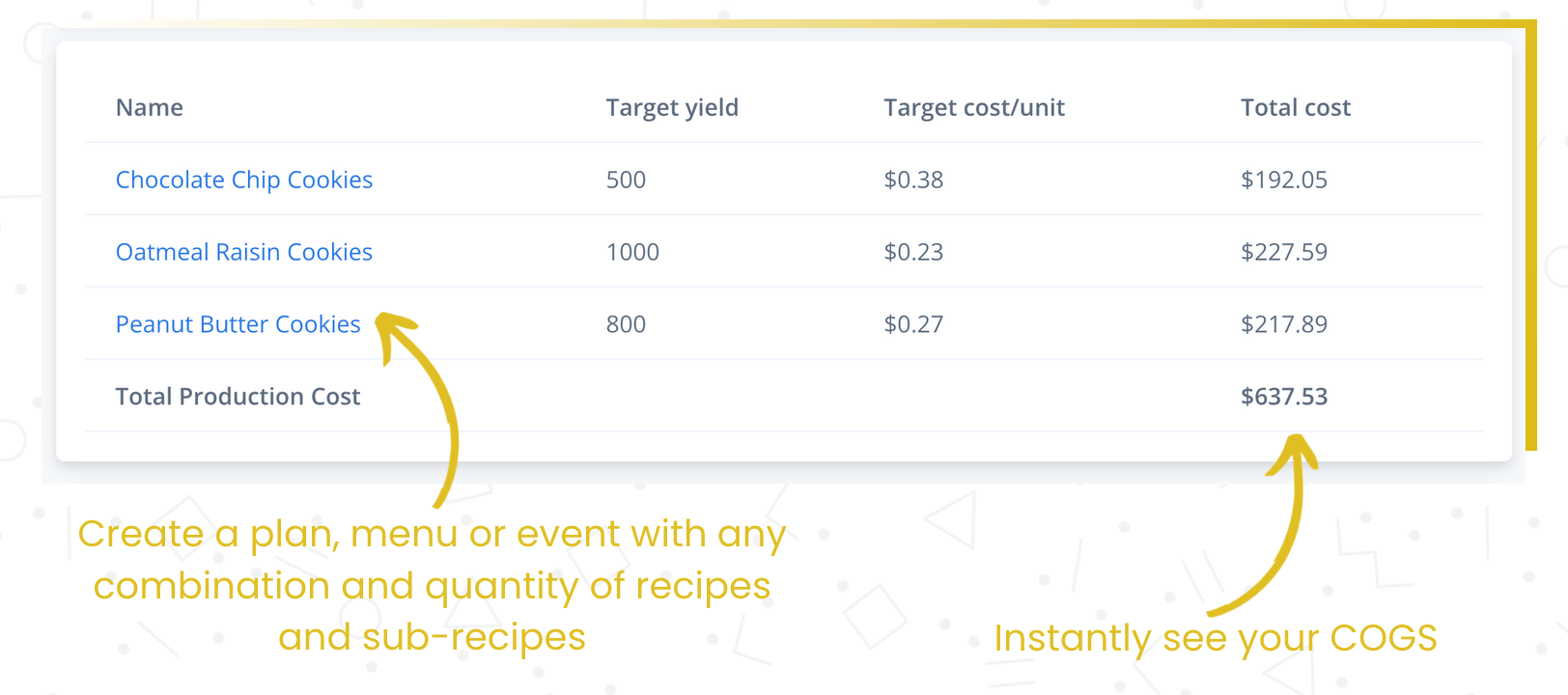

You know what you need to produce this week. Recipe Cost Calculator turns that into a precise plan: select your recipes, set your quantities, and instantly see the total bill of materials — every ingredient, every amount, every cost.

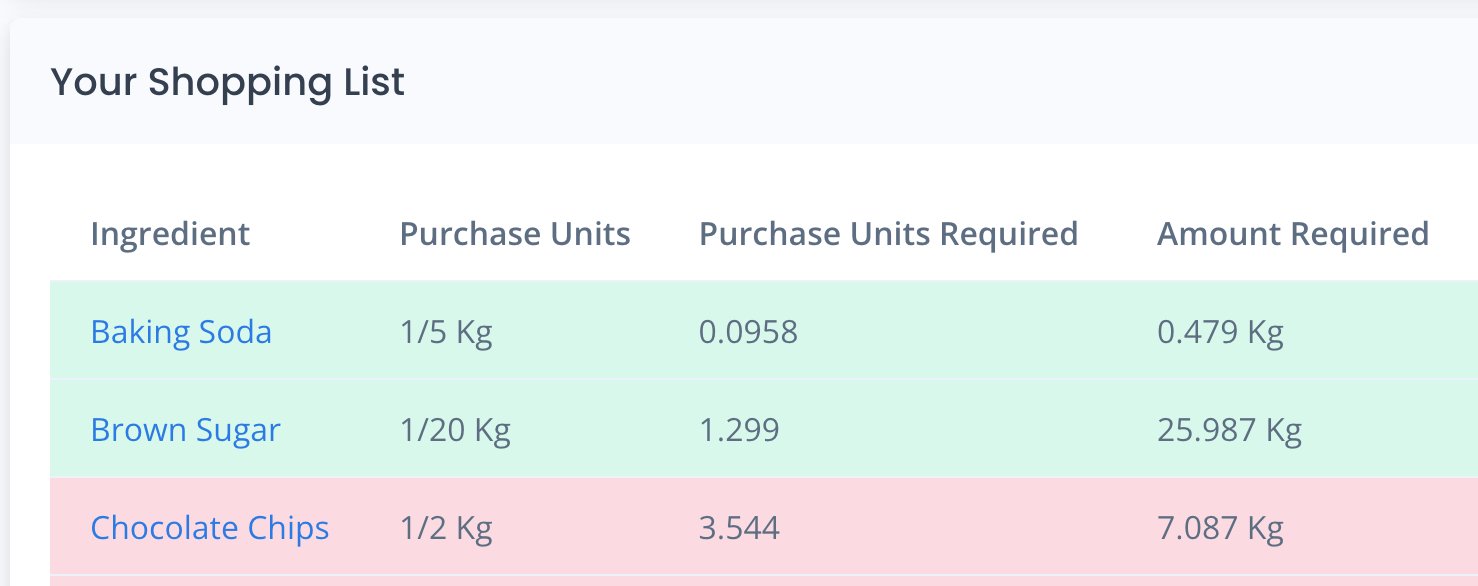

No more over-ordering because you eyeballed it. No more emergency supplier runs because you forgot something. The production plan tells you exactly what you need on hand, and the shopping list shows the shortfall if your inventory doesn't cover it.

We hear from users all the time that production planning saves them 15+ hours a week — time that used to go into manually building prep lists, counting what's in stock, and figuring out what to order. The plan just does all of that for you.

Each production plan shows you the total cost of goods sold for the entire run, broken down by recipe and by ingredient. Scale individual recipes up or down within the plan and watch the numbers update in real time.

The generated shopping list accounts for your current inventory levels, so you only order what you actually need. Export it to Excel, hand it to your purchaser, or use it to create purchase orders directly in Recipe Cost Calculator.

Why this matters

Hours back in your week.

Production planning takes the manual work out of purchasing and prep. You see the total cost of a production run before it happens, order only what you need, and cut the waste that comes from over-ordering or last-minute substitutions. Most users tell us it saves them 15+ hours a week — and their purchasing accuracy goes way up.